Custom Roof Flashing - Metal Work in Vancouver

Flashing are thin pieces of impervious material that is installed to prevent the water from getting into structures from joints, or as a weather-resistant barrier system.

Flashing is very important to roofing systems, flashing keeps your roof airtight and waterproof sealing vulnerable areas to water. These include all joints, edges, or gaps. In areas like these are not sealed properly then, moisture and water can seep in, which will cause severe damage to the structures.

In modern structures, flashing prevents water penetration around chimneys, vent pipes, walls, windows, and door opening to create structures to be more durable and to cut back indoor mold troubles.

Metal Flashing

Many homeowners have removed aging outdoor decks to find siding, sheathing, and framing that has a texture of oatmeal and a place for carpenter ants. In most cases, the major contributors are worms or missing roof flashing. Without flashing nothing prevents water from oozing behind the ledger board which attaches deck framing to the structure.

Metal flashing materials include lead, aluminum, copper, stainless steel, zinc alloy and other components. Metal flashing is a thin layer of waterproof material that keeps water from migrating into places it should not.

Residential roofing typically is a blend of a multitude of materials and surfaces, whose main function is to create a barrier between the interior and the weather. Water is the most difficult element to control. Roof flashing is the protection against water penetration.

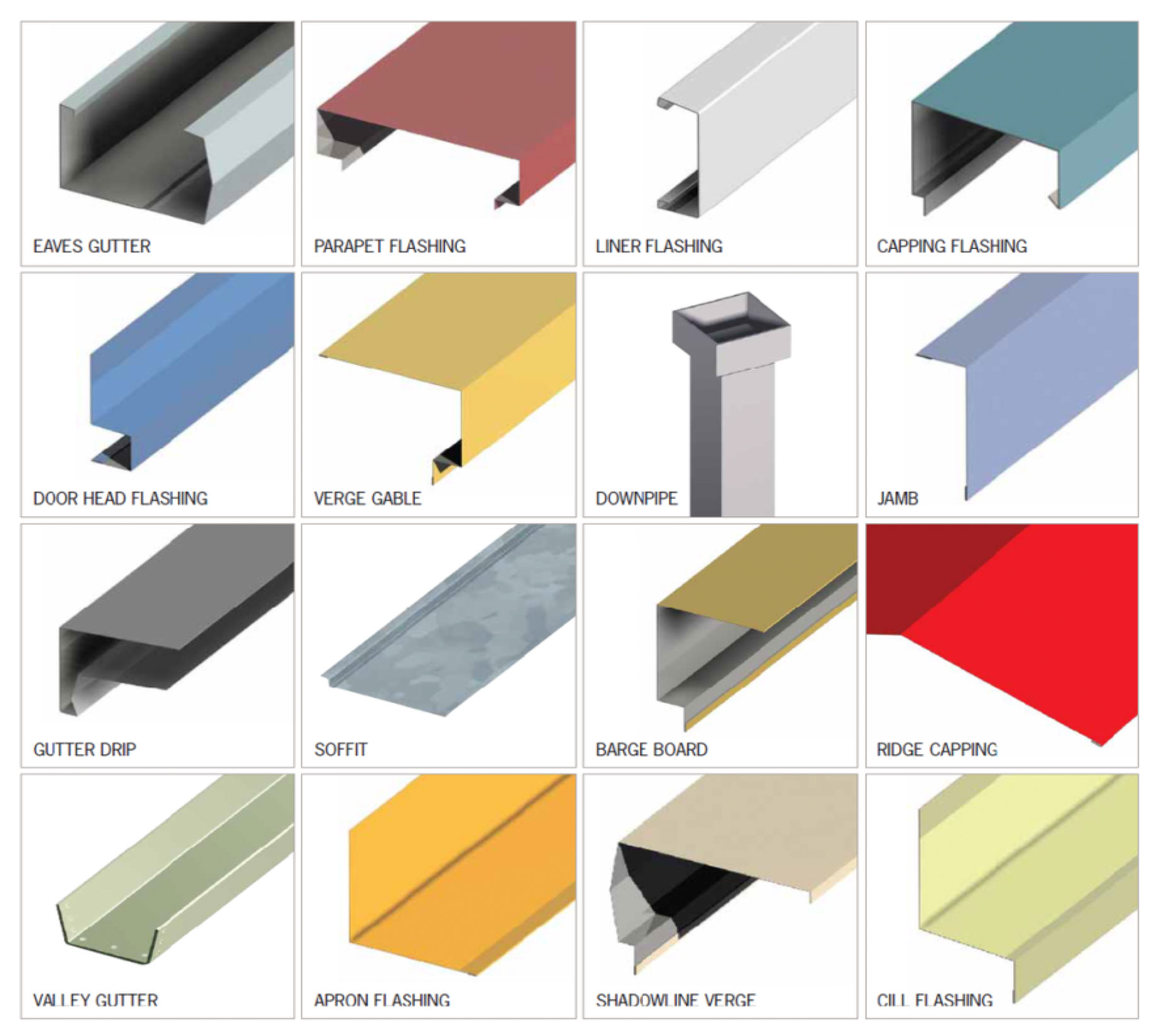

Flashing is used in intersections and terminations on roofing and surfaces to prevent water penetration and usually in areas of valleys, chimneys, roof penetrations, eaves, rakes, skylights, ridges, and roof to wall areas.

Flashing is constructed to combat three systems of water penetrations; gravity, surface tension, and wind pressure. To accomplish this, flashing can be lapped shingle style, soldered or sealed to serve as a continuous surface, or can be constructed with an unbroken profile to breakdown water surface stress.

Roof Flashing materials must be strong, low in up-keep conditions, weather-resistant, able to contain mobility, and be suitable with adjoining materials. A common form of deterioration includes vulnerability to salt air, excessive heat, acid rain, heavy snow, and scouring winds.

Traditional materials and techniques of installing flashing, provide a high building system component. That process requires experience and is very time-consuming.

Many materials can be used for flashing, as long, as it does not scale down in desirability from contact with incompatible materials, and is water-resistant, it should perform.

Centuries ago, carpenters used folded lengths of birch bark to the waterproof intersection of roofs and adjacent walls. There was no water damage, but today builders mostly use these measures:

- Aluminum. Easy to form, durable and relatively inexpensive. Aluminum will corrode if it’s left in contact with alkaline materials like concrete or fiber-cement siding. It also will degrade from contact with the copper-rich-preservatives that have replaced chromated copper arsenate in treated lumber-commonly used in deck framing (these new preservatives also are a problem for fasteners).

- Copper and lead-coated copper. Expensive and harder to form than aluminum-but extremely durable. Copper is compatible with newer types of wood preservatives.

- Lead. Very soft and easy to bend. Durable and a favorite of masons for-chimney flashing. Carries some health risks.

- Galvanized steel. Inexpensive but not as durable as other choices.

- PVC. Easy to work with and inert. Polyvinyl chloride is not affected by-treated wood, an advantage in deck building.

There are four types of roof flashing, all having important roles in keeping rain from infiltrating into homes and running off elsewhere from the home, working in conjunction with the gutter system. Some homes only need one or two of these roof flashing types, and some homes need all four:

- The Drip Edge Roof Flashing: Along the eaves, you’ll find drip edge flashing. This prevents water from a gutter that is overfilled from seeping up under the roof edge and shingles. Without drip edge roof flashing, rain could get under the last shingle or enter under the shingles from a sideway direction. Without drip edge roof flashing, the first damage will be the fascia board, causing it to rot and mold forms and spreads. The next thing damaged is the roof deck and then drywalls inside your home.

- The Valley Roof Flashing: Your roofing contractor will install a felt underlayment over the roof decking, then the roof flashing is installed, followed by the shingles or other roofing material. The valleys are where the two parts of a roof meet, forming a valley. Roof valleys are a key area for shingles to erode without roof flashing, then the roof leaks happen. With roof flashing in the V or W part of a roof, the water runs off to the drip edge roof flashing, into the gutter and away from the house.

- The Vent Pipe Roof Flashing: This roof flashing is a special type that fits tightly around pipes that come through the rooftop. These vents create a weak point for a roof and without roof flashing snugly fit over the round pipes flange, roof leaks start around these protruding areas.

- The Step Roof Flashing: Any chimney or skylight should have roof flashing installed around it so that water moves past it and to the gutter. Step roof flashing is a scale-type arrangement of roof flashing pieces overlapping tightly with each other, slipped under each layer of shingles in the ascending direction.

Advantages of metal flashing for your home are as follows:

- Long-lasting

- Lightweight

- 100% recyclable

- Beautiful

- Rain, wind, and weather-resistant

- UV coatings